In the world of fasteners, the thread is much more than a geometric detail. It is the key component that defines the type of joint, its mechanical strength and compatibility with specific materials. Understanding the different types, functions and applications is essential to ensure a safe and durable assembly.

What is a screw thread?

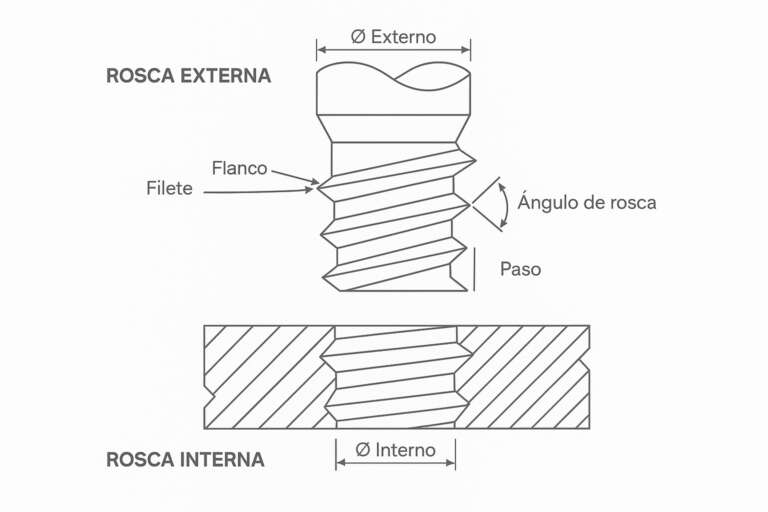

A thread is a helical ridge of uniform cross-section that is wound onto the surface of a cylinder (external thread) or inside a hole (internal thread), allowing fastening by traction and compression.

The main functions of the thread are:

- Transmission of forces: it allows the screw to transmit axial force to the material.

- Assembly security: it prevents loosening due to vibrations or dynamic loads.

Mechanical compatibility: it defines the correct coupling with nuts, plugs or surfaces. - External and internal thread of a screw.

What is thread pitch and why is it important?

The pitch of a thread is the distance between two consecutive threads, measured along the axis of the screw.

- In metric threads, the pitch is measured in millimetres (for example, an M8 with a pitch of 1.25 has 1.25 mm between threads).

- In imperial threads (UNC, UNF, BSW), the pitch is expressed in threads per inch (TPI).

Therefore, the lower the resistance of the material to be fastened, the greater the pitch and the height of the thread or depth of the thread should be. For example, plasterboard requires very large pitches, while wood requires smaller pitches and metal requires even finer pitches.

How does a thread work?

The operating principle of a thread is based on the transformation of rotary motion into linear motion, applying the concept of a helically wound inclined plane on an axis.

When we turn a screw, the thread flange acts as a continuous ramp. The axial advance of the screw (inward or outward from the material) occurs with each complete turn, and the friction between the threads of the screw and the nut (or base material) is what generates the tightening and holds the joint in place.

Most common types of threads in industrial fasteners

In industrial fasteners, different types of threads are used according to standards, geometry and applications:

Metric thread (ISO)

- This is the international standard, with a pitch measured in millimetres and an angle of 60º.

- Widely used in mechanical assemblies, metal structures and industrial components.

Whitworth thread (BSW, BSP)

- Used especially in the British sector and hydraulic connections.

- Its pitch is measured in threads per inch.

Unified Threads (UNC, UNF)

- American standard, widely used in the automotive industry and global industrial systems.

- UNC (coarse pitch), UNF (fine pitch).

Metal thread

- Does not pierce the material, requires a pilot hole.

Sheet metal thread

- Creates its own thread when screwed into an existing hole.

- The thread is designed to cut the material and create a firm connection without the need for a nut.

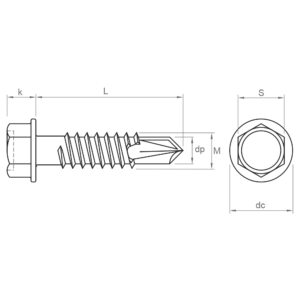

Self-piercing thread

- Pierces and threads in a single step, without the need for a pilot hole.

- Used for quick fastenings in sheet metal or light metal profiles.

- Save time on assembly

How the thread influences the type of fastening

In addition to regulations and the type of assembly, threads are also classified by their geometry and mechanical behaviour when inserted into the base material. These shapes influence the penetration capacity, resistance to loosening and the type of compatible materials.

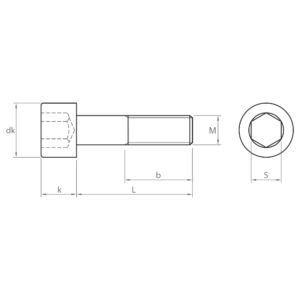

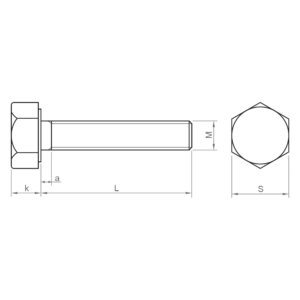

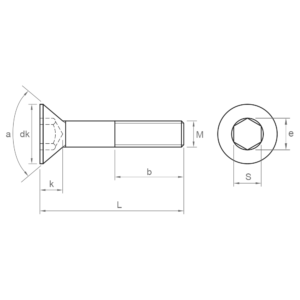

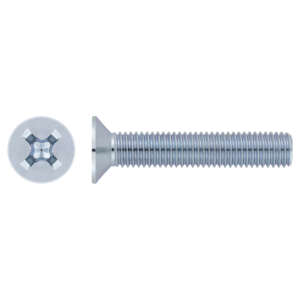

Thread type | Detailed image | Technical characteristics | Common applications |

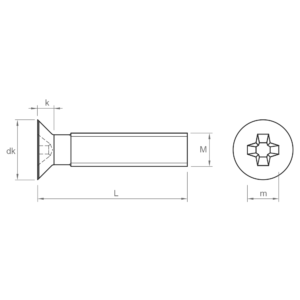

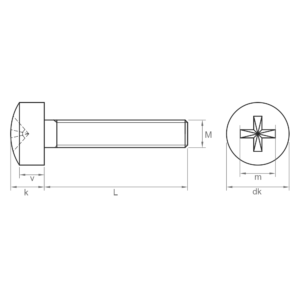

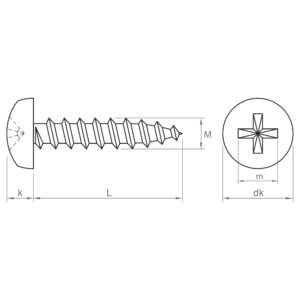

Metric (ISO 17701) |  | 60° thread, normal or fine pitch | Mechanical assemblies, screw-nut |

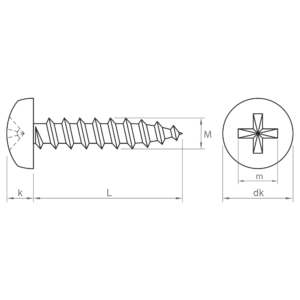

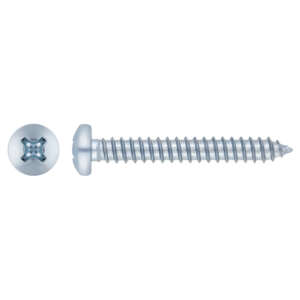

60° self-tapping (ISO 1478) |  | Deforms the metal and creates a virtual nut when screwed in | Steel, aluminium, nylon plugs |

40° self-tapping |  | Smaller angle (less compression), ideal for plastics and wood | Plastic, wood |

High-Low (Hi-lo) |  | Two threads (one high, one low); less insertion effort | Low-density plastics |

Double thread |  | Two threads; each turn advances twice as far | Nylon plugs, chipboard |

Asymmetrical |  | Different angle on flank; good for reversible applications | Nailable plugs, plastics, wood |

With flutes |  | Breaks chips upon penetration; optimal for very hard materials | Steel, bakelite, hard plastics |

Cómo medir una rosca correctamente

Knowing how to measure a thread accurately is essential if you need to ensure compatibility between elements such as screws and nuts or select equivalent spare parts or fasteners. To do this, two fundamental parameters must be identified:

- Outer diameter (nominal): measured with a caliper, taking the widest point of the thread. For example, an M8 screw has an outer diameter of 8 mm.

- Thread pitch: this can be determined with a thread gauge, a sample of thread profiles that allows you to identify the type of thread and its pitch by comparison.

For industrial applications, profile projectors or standard thread gauges can be used. Accurate measurement prevents assembly errors, improves process efficiency and ensures the durability of the fastener.

How to choose the right thread

Choosing the right screw thread is key to ensuring a secure and durable connection, especially in demanding industrial environments. Factors such as pitch, profile and thread type directly influence assembly performance, so it is important to consider factors such as base material, required mechanical strength and type of installation.

- Base material type

- Fine thread for hard materials (steel).

- Coarse thread for all types of materials: wood, plastic, steel, normal or coarse pitch.

- Tensile strength

- A larger pitch means fewer threads and lower load capacity.

- Fine pitches offer better load distribution and precision.

- Project standards

- ISO, DIN, ANSI or BSW according to the required standard.

- Type of installation

- Manual vs automated (requires consideration of tip type and thread design).

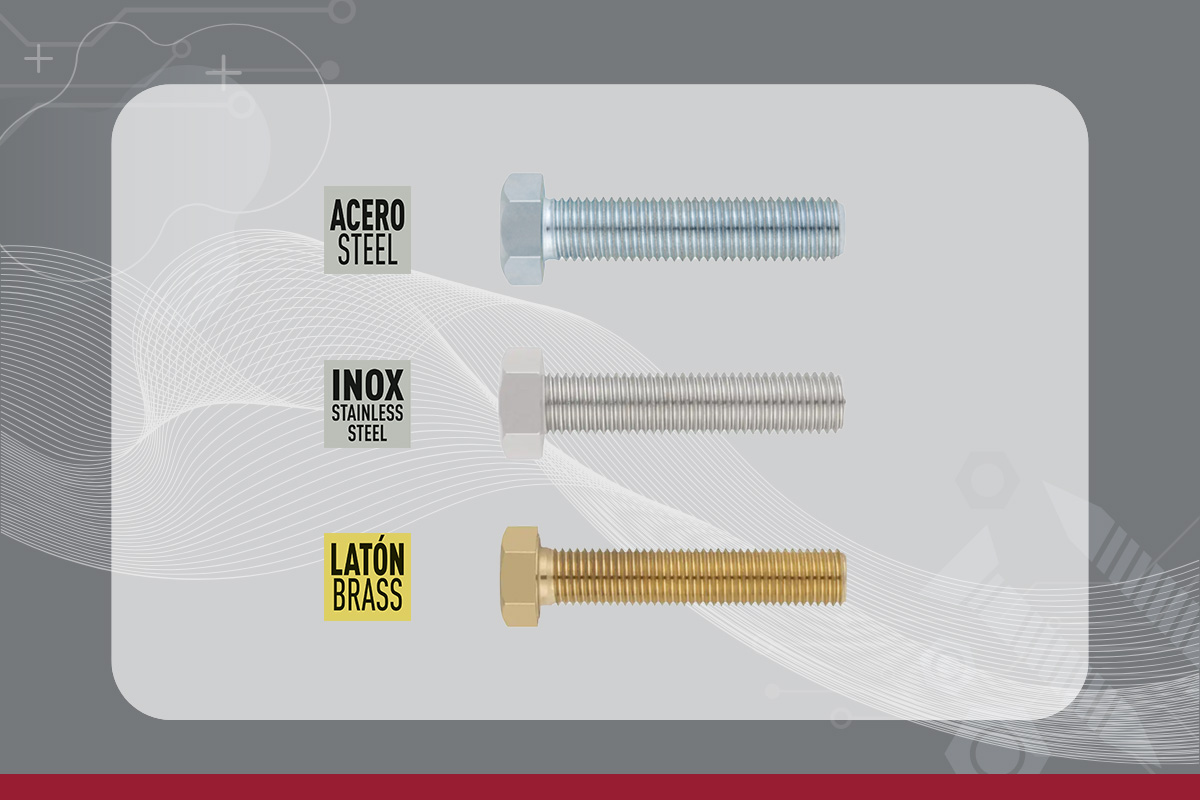

At CHAVESBAO, we have been helping professionals choose the most suitable fasteners for each project for over 50 years. That’s why, beyond the product, we offer you the technical knowledge to make sure everything fits right the first time. Contact us for advice on your next project.