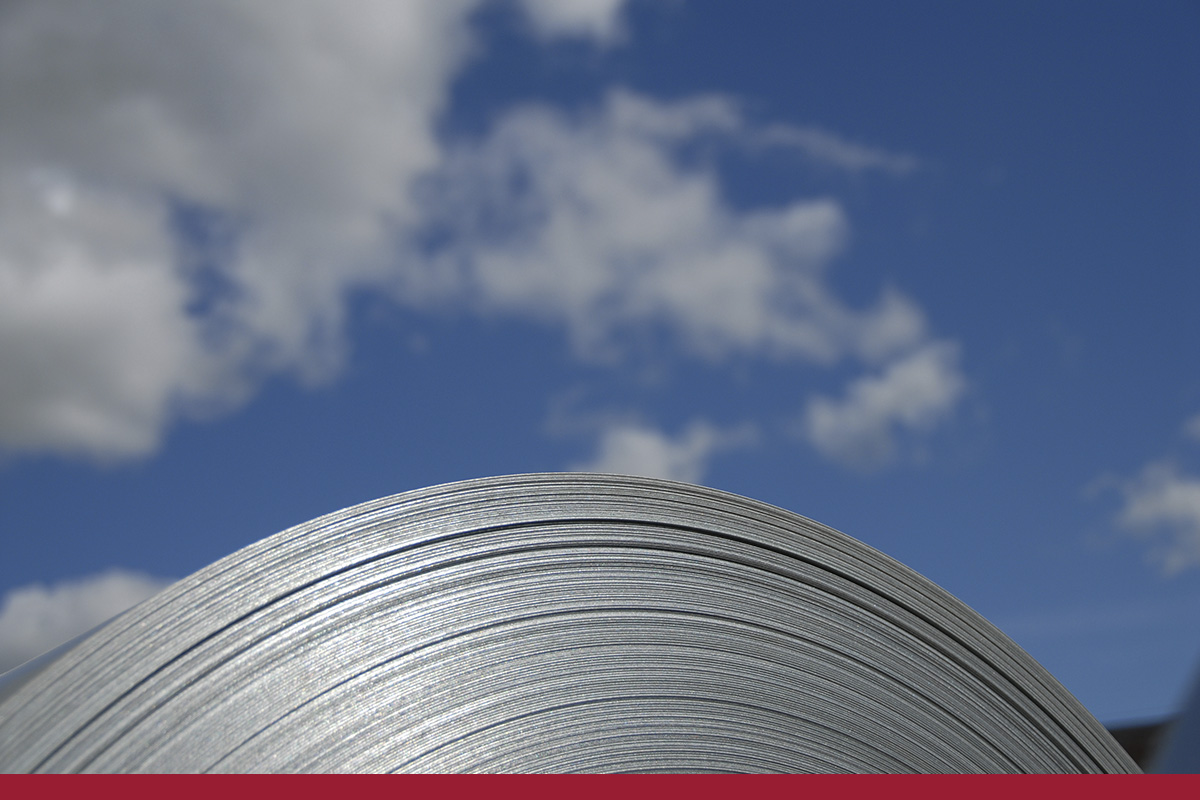

The fasteners made of stainless steel are characterised by having a percentage of chromium in their chemical composition, giving the material a higher resistance to corrosion and oxidation than other types of steel. The different chemical compositions of stainless steels are determined according to the EN 3506 Standard and are classified into: corrosion resistant steels; refractory steels -for high temperatures-; and creep resistant steels. What are the characteristics of corrosion resistant steels such as A2 (AISI 304) and A4 (AISI 316) stainless steels? Discover their properties and main differences.

Properties of A2 stainless steel (AISI 304)

A2 stainless steel, also known as AISI 304, is composed of chromium -about 18%-, nickel -approximately 10%- and other metals such as carbon, manganese, phosphorus and sulphur in smaller proportions. It has a bright surface finish which gives it an aesthetic touch for surface applications. Although it must be taken into account that the material from which it is made is not resistant to salt and seawater.

Among the mechanical properties of A2 stainless steel (AISI 304) we can highlight the resistance to corrosion -even at high temperatures- and good ductility and toughness. This allows the material to deform without breaking and it can withstand high impacts. Another characteristic of this type of steel is its ease of forming. This means that it can be used in welding, cold forming and machining processes.

Characteristics of stainless steel A4 (AISI 316)

Stainless steel A4 or AISI 316 has the same chemical composition as stainless steel A2 (AISI 304), but molybdenum is added. Molybdenum is a chemical element that is characterised by providing the material with greater resistance to corrosion, which makes A4 (AISI 316) stainless steel fasteners ideal for use in corrosive and marine environments. It is particularly resistant to pitting corrosion and stress corrosion cracking.

Unlike A2 stainless steel (AISI 304), A4 stainless steel (AISI 316) is somewhat less malleable and can be formed by machining and welding techniques. It is also resistant to high temperatures and is ideal for use in marine environments.

A2 (AISI 304) and A4 (AISI 316) Stainless Steel Applications

Although A2 (AISI 304) and A4 (AISI 316) stainless steel have similar properties, when choosing which of the two types to apply in your projects, you must take into account the specifications of each of them. Both are used in screws, nuts, washers and other elements, but what are the most common applications of each of them? In the following table you will find the details:

Stainless steel A2 (AISI 304)

Food industry: production machinery |

Hospital equipment: furniture |

Automotive industry: car accessories |

Household appliances such as refrigerators, washing machines and dishwashers. |

Stainless steel A4 (AISI 316)

Maritime sector: shipbuilding |

Hospital equipment: furniture |

Installation of pipelines to transport fluids |

Construction in environments exposed to moisture |

In addition to all these examples, at CHAVESBAO we recommend that you analyse the specific properties required for each type of application before selecting the product. In our catalogue you will find a wide selection of fasteners made of A2 (AISI 304) and A4 (AISI 316) stainless steel: screws, nuts, eyebolts, rods and many more products.

If you have any questions, please contact our sales team using the contact form or by email at info@chavesbao.com.