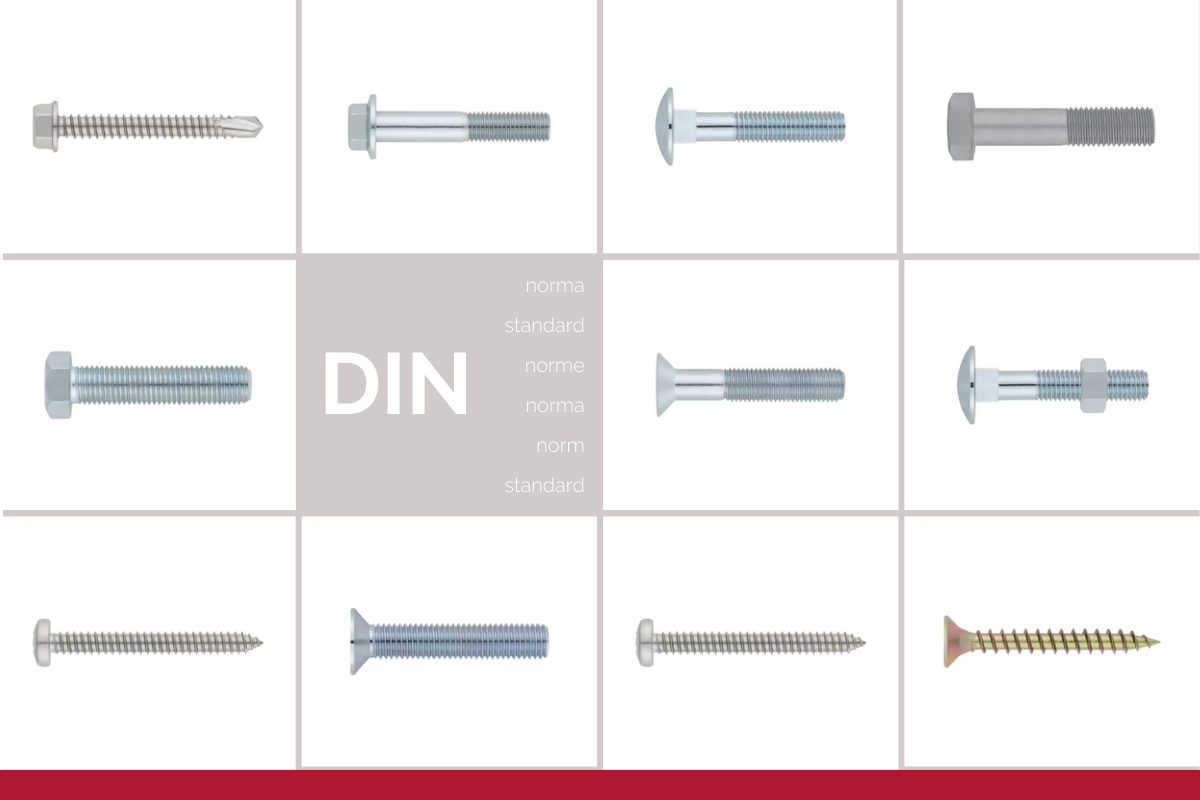

When it comes to fasteners, choosing the right material is an important decision. It directly affects the durability, strength and safety of any installation. In this guide, we analyse the three most common materials used in fasteners: carbon steel, stainless steel and brass. We compare their characteristics, applications and advantages to help you make the best decision for your industry or type of project.

Comparison of materials and their applications in industry

MATERIAL | MAIN CHARACTERISTICS | COMMON APPLICATIONS |

Carbon steel | High mechanical strength, economical | Construction, automotive, metal structures |

Stainless steel | Corrosion resistant, attractive appearance | Food, maritime, outdoor, solar energy |

Brass | Good corrosion resistance, excellent conductivity | Plumbing, electricity, decorative components |

The choice of material depends on the environment, mechanical demands and regulatory requirements. For example, in aggressive or outdoor environments, stainless steel is the safest option. On the other hand, for internal structures or fasteners without direct environmental contact, carbon steel is more economical and effective.

Analysis of materials: carbon steel, stainless steel and brass

Carbon steel: strength and competitive cost

Stainless steel: maximum corrosion resistance

- Advantages:

- Corrosion resistance, even in marine or chemical environments.

- High durability without the need for coatings.

- Compliant with hygiene and health regulations.

- Limitations:

- Higher cost than carbon steel.

- May exhibit thermal expansion in certain applications.

Stainless steel fasteners are the preferred choice in sectors where corrosion is critical or aesthetics are important.

Brass: versatility and chemical resistance

- Advantages:

- Good resistance to humid environments and mild acids.

- Easy to machine, perfect for plumbing and electrical parts.

- Antimagnetic and decorative properties.

- Limitations:

- Lower mechanical strength than steels.

- Not suitable for high structural loads.

Recommended for electrical installations, valves, taps and non-structural fasteners.

How to identify the right material for the type of installation

Before choosing the right screw, it is essential to analyse the conditions of the project. To do this, it is important to answer the following questions:

1. Is it exposed to moisture, chemicals or the elements?

✅ Choose stainless steel for its high resistance to corrosion.

2. Does it require high mechanical loads or critical fastenings?

✅ Prioritise high-strength carbon steel.

3. Are aesthetics or surface finish important?

✅ Brass or stainless steel offer a better visual appearance.

4. Do you need to comply with health or food regulations?

✅ Choose A2 or A4 stainless steel, which guarantee safety.

At CHAVESBAO, we provide technical advice to ensure precision, safety and durability in your projects. Our catalogue includes carbon steel, stainless steel and brass fasteners that meet the requirements of every industry.

The correct selection of fastener material is key to ensuring the service life and performance of any installation. If you still have questions about which screw is right for you, our technical team is at your disposal to offer you the best customised solution. Contact us.