Kanban is an automated supply system that optimises stock management and makes it profitable. The Kanban service at CHAVESBAO allows clients to achieve significant time and cost savings in their procurement, logistics and production systems.

Our commercial team analyses the clients’ needs and consumption to correctly scale the Kanban system. Additionally, assistance is provided during the full implementation of the service.

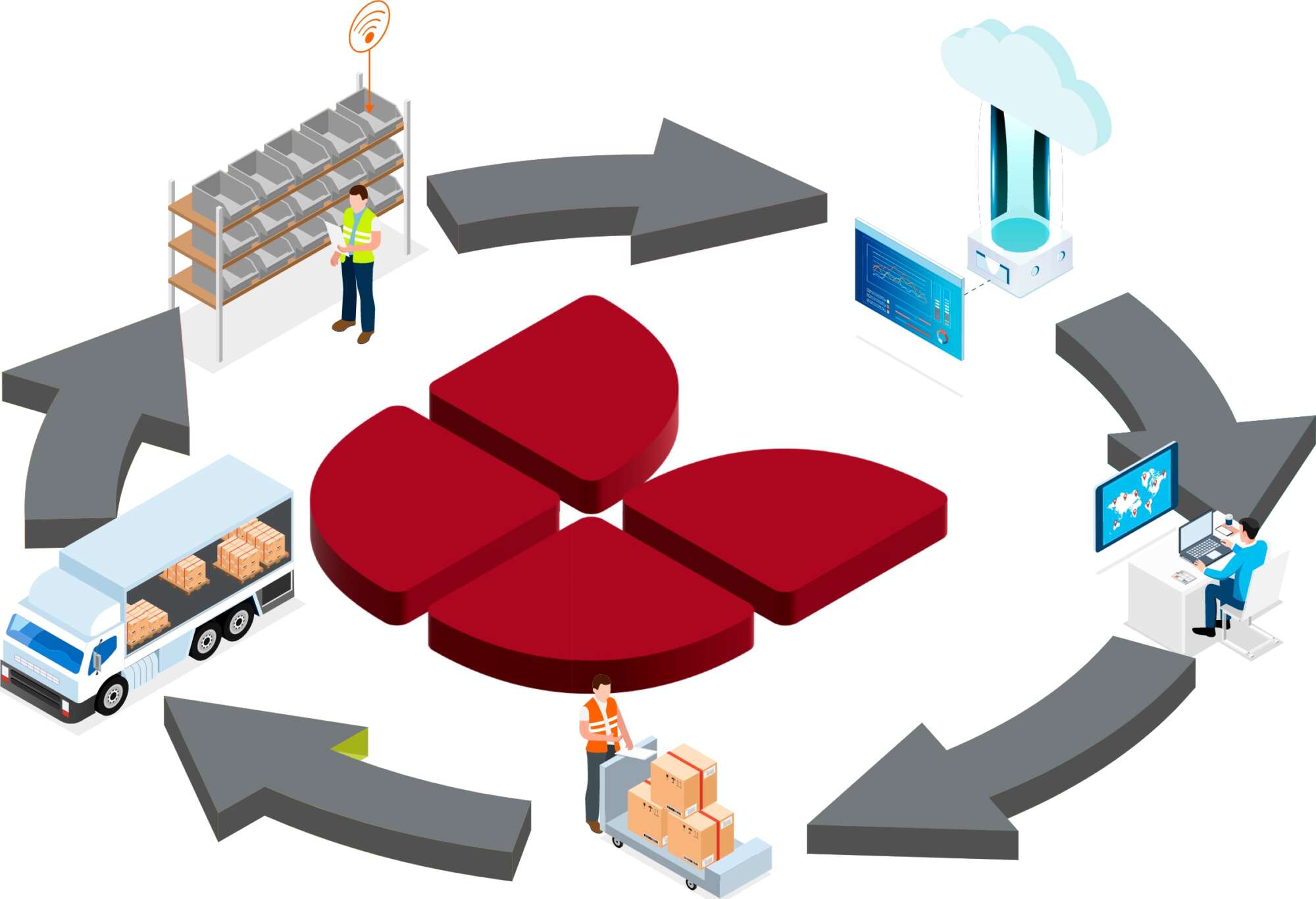

1. RFID reading

Readings are carried out on the boxes consumed by the client.

1. RFID reading

2. Data management

The data is transferred to the CHAVESBAO ERP where an automatic replenishment order is generated.

2. Data management

3. Creation of the order

The CHAVESBAO Commercial Department reviews the order and sends the confirmation to the client.

3. Creation of the order

4. Preparation

The order is prepared for replenishment.

4. Preparation

5. Delivery

The goods are delivered to the client.

5. Delivery

1. RFID reading

Readings are carried out on the boxes consumed by the client.

2. Data management

The data is transferred to the CHAVESBAO ERP where an automatic replenishment order is generated.

3. Creation of the order

The CHAVESBAO Commercial Department reviews the order and sends the confirmation to the client.

4. Preparation

The order is prepared for replenishment.

5. Delivery

The goods are delivered to the client.

The workflow is optimised and costs and wait times are reduced in the replenishment, receipt and inventory taking, which means greater efficiency in production.

Stock control avoids oversizing, as well as stock depletion. It also facilitates the location of materials, achieving a well organised warehouse.

A more exhaustive understanding of consumption is obtained in real time, facilitating decision making with real data. The material is always available, without stopping production.

Savings are obtained in costs and resources allocated to management of administrative and logistics work of stock maintenance.

The label has an RFID circuit with the information of the barcode or BIDI code. The product data is recorded on it, such as the reference or quantity.

The label is attached on the front. It helps to optimise storage and reduce the storage area.

The shelves have and RFID antenna on the upper shelf, where the consumed boxes are placed so that the replenishment is considered.

The RFID labels and put in the box so that the replenishment orders can be generated.

Reading of the labels can also be carried out with a mobile.