Metric threads are one of the most widely used threading systems in industrial fasteners. Their standardisation allows for great compatibility between screws, nuts, and mechanical components in all types of assemblies. Understanding how to read, calculate, and apply them correctly is key to ensuring secure joints, avoiding assembly errors, and selecting the right spare parts.

What is a metric thread and how is it classified?

A metric thread is defined by the ISO (international system), where dimensions are in millimetres. It is used in both screws and nuts and allows for standardised compatibility between manufacturers and industrial sectors.

Metric threads are defined by three main parameters:

- Nominal diameter (D): the outer diameter of the screw.

- Pitch (P): the distance between consecutive crests.

- Type of fit: loose or tight, according to ISO tolerances.

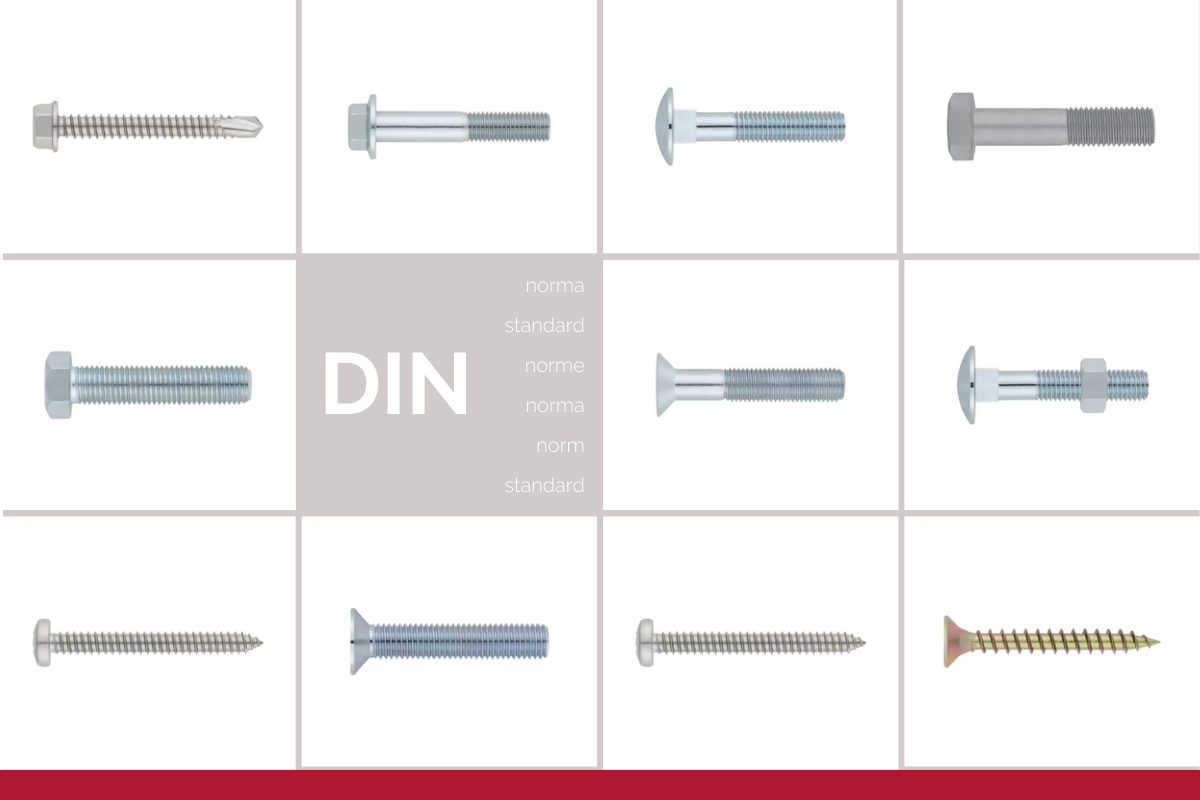

There are also profile variants such as the MJ type (more common in aeronautics), but the most common in general industry is the ISO Metric M thread according to DIN 13.

How to read a metric thread table?

Metric thread tables compile the most common standard values for screws, nuts and threaded parts. Reading them allows you to select the correct type according to the application, pitch and required tolerances.

To interpret them correctly, it is important to understand three essential parameters:

- Nominal diameter (D): corresponds to the outer diameter of the screw or external thread, expressed in millimetres. Example: M10 = 10 mm. The letter M indicates that it is a metric thread with a pitch in millimetres.

- Pitch (P): this is the distance between two consecutive thread crests. It is expressed in millimetres and can be standard or fine.

- Type of fit: determines the degree of clearance between the male and female threads. It can be free (loose fit) or tight (with less tolerance), which influences the resistance to loosening and ease of assembly.

When you see a measurement such as M10 × 1.5 in a table, you are looking at a code with three key pieces of information:

- M10 → the screw has an external diameter of 10 mm.

- 1.5 → this is the pitch, i.e. the distance between threads.

- Base drill (∅8.5 mm) → diameter of the hole required if you are going to make an internal thread with a male thread.

Technical tip: with fine pitches (such as 1.0 or 0.75), the fit is more precise and is recommended for vibrations or thin parts. For fine threads or special pitches, always consult the specific tolerances of the corresponding ISO or DIN standard.

What do codes such as M6 × 1 × 6H mean?

In technical and industrial applications, you may encounter codes such as ‘M6 × 1 × 6H’. This indicates:

- M6 → Nominal diameter 6 mm.

- 1 → Thread pitch (1 mm).

- 6H → Female thread tolerance (ISO).

These values ensure that the part is compatible with its corresponding male screw or female nut under ISO standards.

How can you tell if a thread is metric or Whitworth?

One of the key differences between metric and Whitworth threads is:

- The thread angle: 60° in metric threads (ISO), 55° in Whitworth (BSW).

- Measurement system: Metric (in mm), Whitworth (threads per inch – TPI).

- Thread shape: Whitworth threads have a more rounded profile, while metric threads are sharper.

To identify it correctly, you can use a thread gauge and check the equivalence tables. It is important to do this, as both may have similar diameters but are not compatible.

Technical tip: if you have any doubts, measure the pitch with precise tools and always consult the official DIN/ISO or BSW tables to avoid assembly errors.

How to calculate the drill bit diameter for taps

The general formula most commonly used by technicians and installers is: Drill diameter (Dt) = Nominal diameter – Thread pitch

Practical example: If you need to thread a hole for an M8 × 1.25 screw, the drill should be: 8 – 1.25 = 6.75 mm

In the technical table, this is normally rounded up to 6.8 mm to ensure good threading without risk of breakage.

How can you determine the pitch of a metric thread?

If you already have the screw or nut and need to identify it:

- Measure the outside diameter with a caliper.

- Determine the pitch using a thread gauge or by comparing it to a chart.

- Consult a metric thread chart to confirm compatibility.

If you do not have specific tools, you can compare it visually with an already identified screw or a printed template. You can also consult this article on how to measure a thread correctly.

What are the differences between standard thread and fine thread?

- Standard thread (coarse pitch) → most common, ideal for general use.

- Fine thread → better for vibrations, thin surfaces or precise adjustments.

Simplified example table:

| Diameter | Standard | Fine pitch |

| M6 | 1.00 mm | 0.75 mm |

| M8 | 1.25 mm | 1.00 mm |

| M10 | 1.50 mm | 1.25 mm |

We have prepared a table of metric threads with diameters, pitches, and drill sizes to facilitate your selection.

Are you unsure about the right type of thread or drill bit?

At CHAVESBAO, we help you choose the correct fastener according to DIN or ISO standards. Consult us and secure every joint from the outset.