Measuring a screw correctly is key to selecting the right fastener and ensuring the correct fit in any industrial or mechanical assembly. Although it may seem simple, an error in diameter, length or thread pitch can lead to poor joints, premature wear of parts or damage to threads and assembly components.

In this practical guide, we explain step by step how to measure a screw, what instruments to use, and what measurements are really important for identifying it correctly.

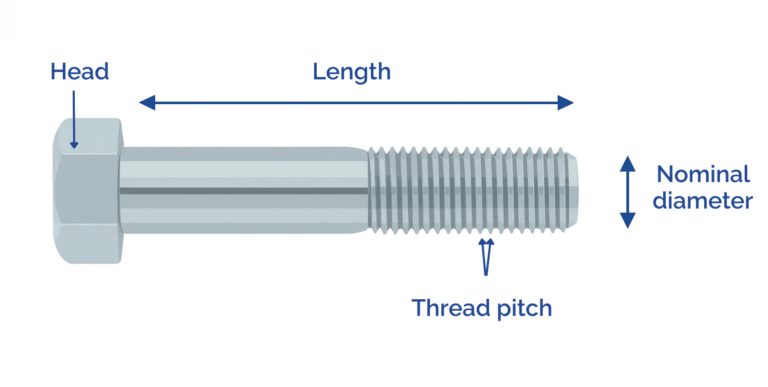

What measurements define a screw

A screw is mainly identified by four key parameters, which determine its compatibility with the hole or nut where it will be fastened:

Nominal diameter

This is the most important measurement and refers to the outer diameter of the thread. In metric screws (DIN/ISO), it is usually expressed in millimetres (M6, M8, M12, etc.). Example: an M8 screw has an outer diameter of 8 mm.

Length

This is the distance from the base of the head to the end of the screw. For countersunk screws, the length includes the entire head. For hexagonal screws or socket screws (except DIN 7991), only the body is measured, excluding the head.

Thread pitch

Defines the distance between consecutive thread crests. In standard metric units, it is expressed in millimetres (e.g. 1.25 mm pitch). See our guide on thread types and their applications.

In fine-threaded screws, this pitch is smaller to increase vibration resistance or achieve a more precise fit. For example, a standard M8 screw has a pitch of 1.25 mm, while its fine-threaded version may have a pitch of 1.0 mm or less, depending on the standard.

Head type and shape

Determines the tightening tool (hexagonal, Allen, Torx, slotted) and how the screw head integrates into the assembly.

Recommended tools for measuring a screw

To obtain accurate measurements and avoid errors, it is important to use the right tools. These are the most common instruments in industrial environments and workshops:

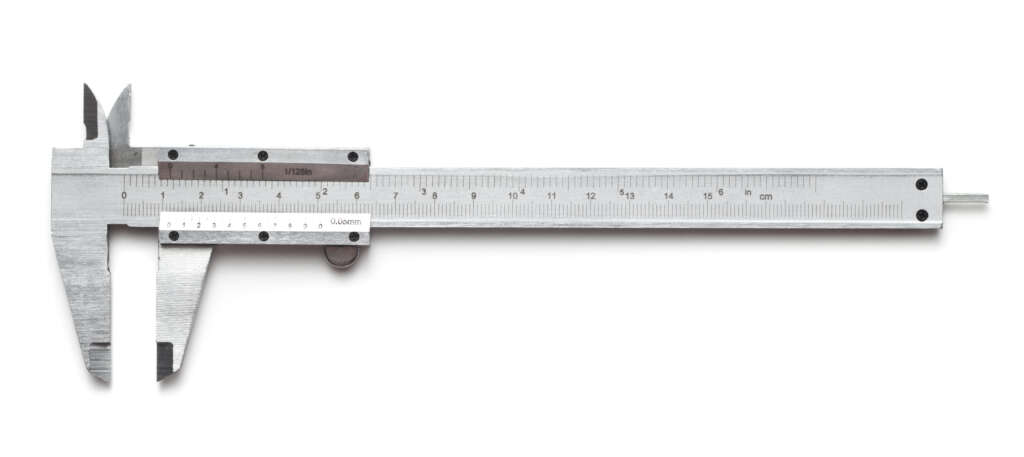

Calipers

This is the most accurate tool for measuring the diameter and length of a screw. It provides highly accurate measurements in millimetres.

- It is used to measure the outer diameter of the thread.

- It can also be used to measure the length from the base of the head to the end of the screw.

- Some models include thread gauges that make it easy to identify the screw pitch.

Tape measure

Suitable when a quick and approximate measurement is needed, especially for length. Not recommended for measuring small diameters, as visual error may occur.

Thread comb

Tool designed to identify the thread pitch of a screw. The comb is adjusted over the thread until the pattern that exactly matches the pitch is found, allowing the measurement to be compared with the corresponding DIN or ISO tables.

How to measure a screw step by step

Step 1: Measure the diameter

Place the screw in the vernier caliper and measure the outer diameter of the thread. This measurement defines the nominal size of the screw. Example: if it measures 6 mm, it is an M6 screw.

Step 2: Measure the length

Screws with protruding heads (hexagonal, Allen, carriage): measure from the base of the head to the tip.

Countersunk screws: measure the total length, including the head, as it is flush with the material.

Use a gauge or tape measure to obtain the length in millimetres.

Step 3: Identify the thread pitch

Use a thread gauge to determine the pitch. Fit the gauge until it matches the thread ridges. In standard metric sizes, you will see values such as 1.0 mm, 1.25 mm or 1.5 mm. In metal screws, the most common pitch is coarse.

Paso 4: Verificar el tipo de cabeza

Observa la forma y huella de la cabeza, ya que influye en el tipo de herramienta necesaria y en la aplicación:

- Hexagonal: montaje con llave.

- Allen (huella hexagonal interna): ideal para espacios reducidos.

- Avellanada: queda oculta en la superficie.

- Alomada o redonda: uso en carpintería metálica o piezas vistas.

Important note:

A common mistake is to confuse a metric screw with an imperial screw of a similar size. To avoid this, always check the thread pitch with a suitable thread gauge or consult the screw specifications.

How to interpret measurements to identify the screw standard

Measuring a screw correctly not only allows you to know its diameter and length. These dimensions also help to identify its manufacturing standard (DIN, ISO, UNE), which defines key aspects such as thread pitch, head type and mechanical or dimensional tolerances.

This makes it easier to:

Select the right fastener for each assembly.

Ensure compatibility with standard nuts, washers and tools.

Make quick and accurate replacements without having to measure all dimensions.

Avoid mistakes when choosing fasteners with similar measurements but different properties, such as fine thread screws versus standard screws.

Knowing the measurements and standards of a screw allows you to select the correct fastener, avoid incompatibilities and optimise assembly and maintenance processes. In any industrial environment, measuring a screw correctly is the first step in ensuring the safety and efficiency of the joint.

If you need technical advice, please do not hesitate to contact us.