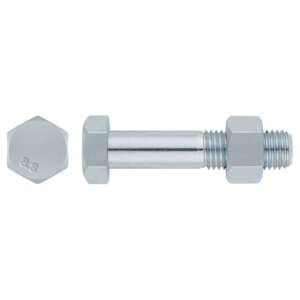

When assembling metal structures, choosing the right fasteners is critical to ensuring the safety and regulatory compliance of the project. Two of the most widely used standards for structural fasteners are EN 15048 (for non-prestressed joints) and EN 14399-4 (for prestressed joints with HV systems).

This guide is designed to help installers, site managers and technical managers make the right decision based on the specific needs of each construction project.

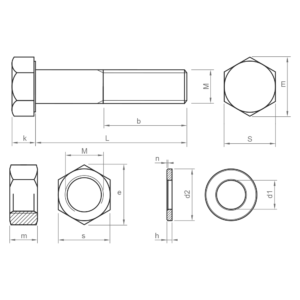

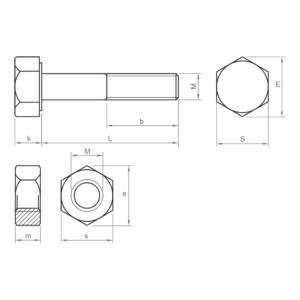

Key technical differences in structural bolts

Preload vs. no preload

- EN 15048: designed for structural joints without the need for preload. It is used when the forces acting on the structure are transmitted mainly by direct contact between surfaces.

- EN 14399-4: requires pre-tensioned joints, where a controlled tightening torque is applied to generate tension in the bolt. This improves performance under variable loads, vibrations and tensile stresses.

Installation methods

- EN 15048:

- Does not require exhaustive control of the tightening torque.

- Simple installation with standard tools.

- Lower cost and assembly time.

- EN 14399-4:

- Requires controlled tightening procedures (controlled torque method, controlled rotation or direct tension).

- Requires qualified personnel and torque or tension control tools.

- Preferable in structures with high structural responsibility.

Selection criteria

Type of load

- Static load (predominantly compression or shear): EN 15048 is sufficient.

- Dynamic or variable tensile load (bridges, cranes, structures with vibrations): EN 14399-4 is the recommended option.

Structure environment

- Indoor or protected environments: EN 15048 galvanised may be suitable.

- Outdoor environments, coastal or industrial areas with risk of corrosion: CHAVESBAO offers HDG (hot-dip galvanised) versions for both standards.

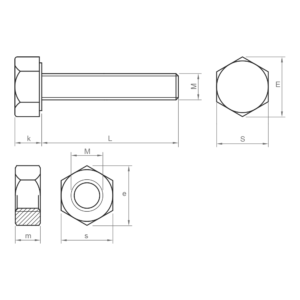

Case studies and examples of structural screw applications

Case 1: Standard industrial building

- Recommended solution: EN 15048 set screw.

- Reason: static loads, modular structure, quick assembly and no need for pre-tensioning.

Case 2: Steel footbridge

- Recommended solution: EN 14399-4 bolt set.

- Reason: tensile requirements, possible vibrations, need for pre-tensioning for greater structural safety.

Case 3: Photovoltaic plant in coastal area

- Recommended solution: EN 15048 or EN 14399-4 with HDG coating.

- Reason: highly corrosive environment, need for corrosion protection, variable loads depending on the structure.

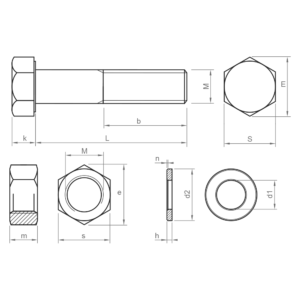

Recommendations for structural bolt sets

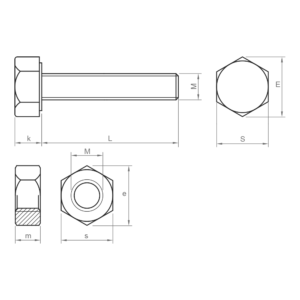

- EN 15048 8.8 HDG screw set:

- Ideal for common metal structures.

- Quick assembly with common tools, ideal for optimising installation times on site.

- EN 15048 8.8 ZP screw set:

- Recommended for indoor structures or controlled conditions.

- Electrolytic finish offering basic protection against corrosion.

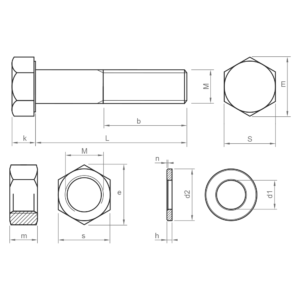

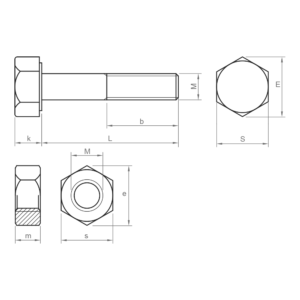

- EN 14399-4 HV system screw set HDG:

- Designed for pre-tensioned joints in high-responsibility structures.

- High mechanical performance and corrosion resistance.

- EN 14399-4 HV ZP system screw:

- Alternative for interiors or moderate environments where pre-tensioning is required.

- Zinc finish for adequate protection in non-aggressive conditions.

- EN 14399-4 HV 10.9 BL screw system:

- Functional solution for structures with subsequent treatments or without direct exposure to the elements.

- Available in black for projects requiring painting or aesthetic finishing.

Consult our structural fasteners catalogue to learn more about the complete range.

Choosing the right EN 15048 or EN 14399-4 structural fastener set not only ensures regulatory compliance, but also the safety and efficiency of the assembly. At CHAVESBAO, we offer personalised technical advice and a complete range of certified solutions so that everything fits perfectly in every structural project.