DIN fasteners include screws, nuts, washers and other fastening elements manufactured according to standards established by the Deutsches Institut für Normung (DIN). These specifications ensure precise dimensions, controlled tolerances and universal compatibility.

Thanks to this standardisation, DIN fasteners are key in many sectors, guaranteeing precision, mechanical strength and interchangeability of parts.

Types of DIN fasteners: screws, nuts, washers, rods and other standardised fasteners

This set of fasteners includes various elements designed to perform specific functions within joining systems. From the screws that secure the main fastening to the nuts and washers that provide stability and distribute the load, each piece meets technical criteria defined by its corresponding standard.

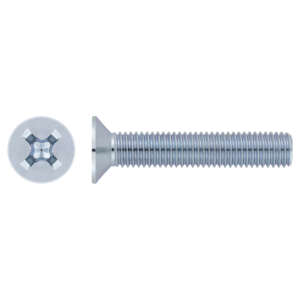

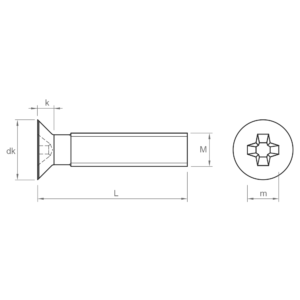

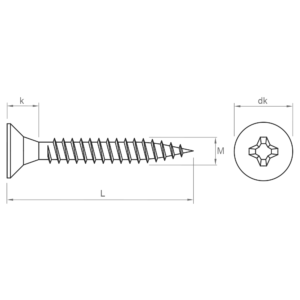

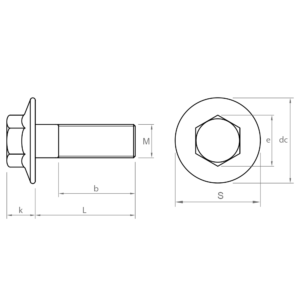

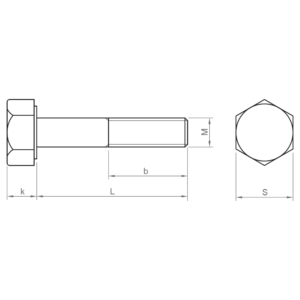

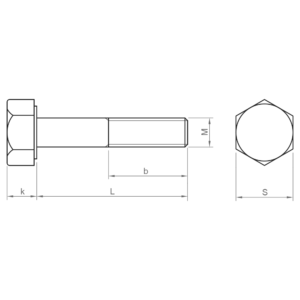

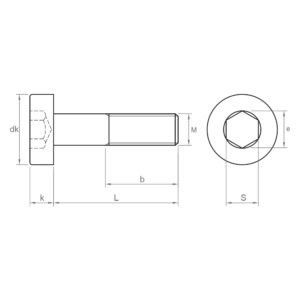

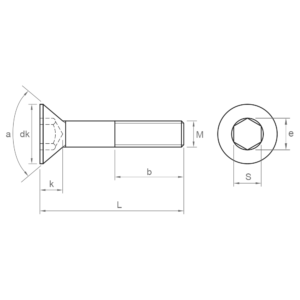

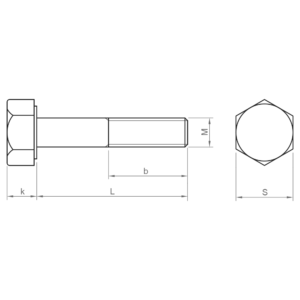

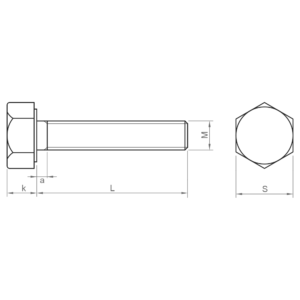

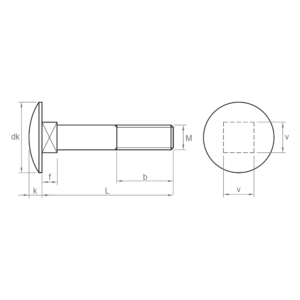

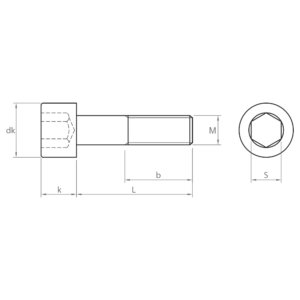

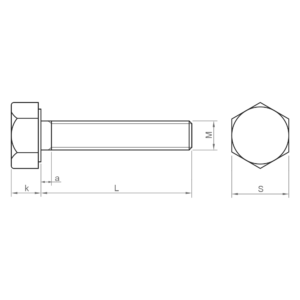

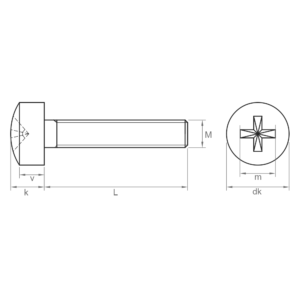

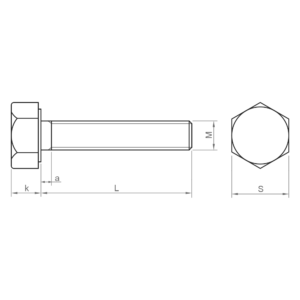

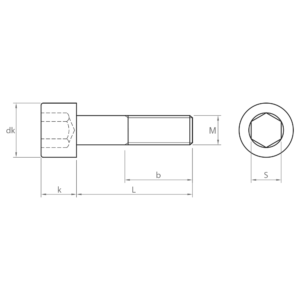

The range includes hexagon screws with full thread (DIN 933) and partial thread (DIN 931), commonly used in structural joints and in the assembly of high-strength structural screws. Socket screws (DIN 912) provide secure internal tightening in precision machinery and systems, while metal screws (self-drilling or self-tapping) are specifically designed for fastening sheet metal, profiles or metal components.

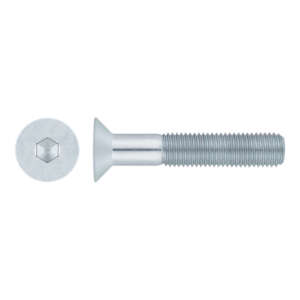

Other models, such as countersunk (DIN 7991) or flange head screws, allow for a flush finish or better load distribution depending on the type of application.

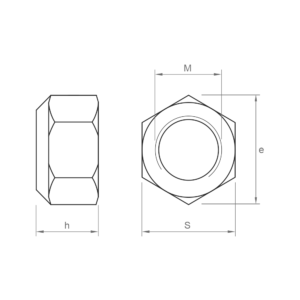

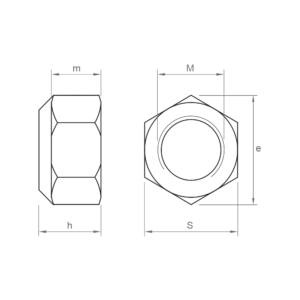

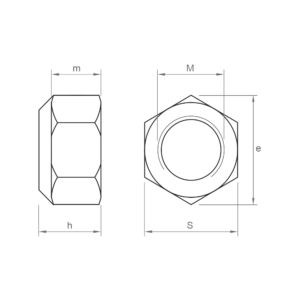

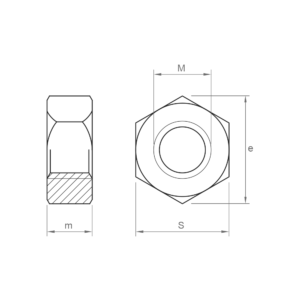

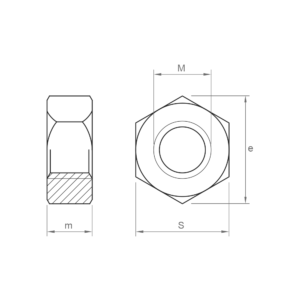

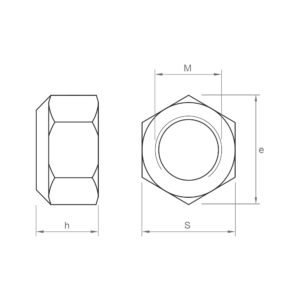

Hexagon nuts (DIN 934) are the most common type of threaded fastener, used together with metric bolts in machinery, structures and industrial assemblies.

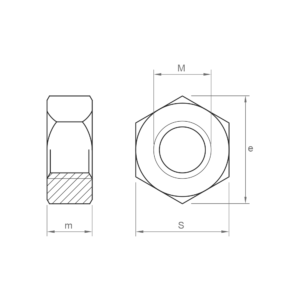

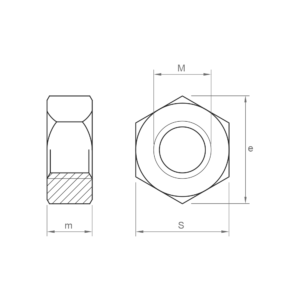

In applications involving vibration or dynamic loads, self-locking nuts (DIN 985) are used, which incorporate a nylon ring or a metal retaining system to prevent loosening.

For structural joints subjected to high stresses, the range also includes high-strength structural nuts. In addition, DIN standard nuts include specific variants such as blind nuts, flanged nuts and safety nuts, adapted to different assembly and finishing requirements.

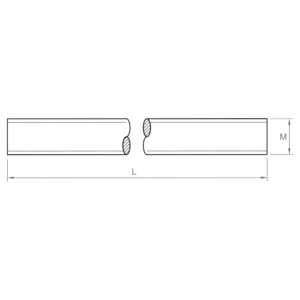

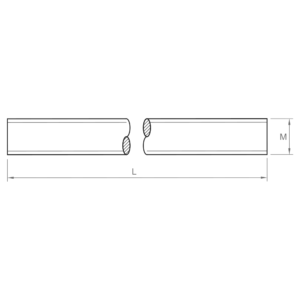

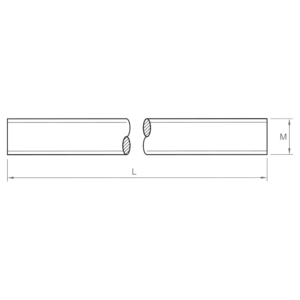

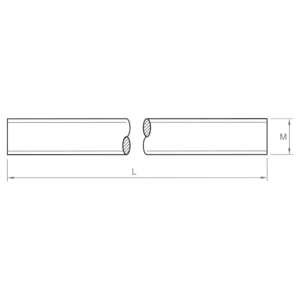

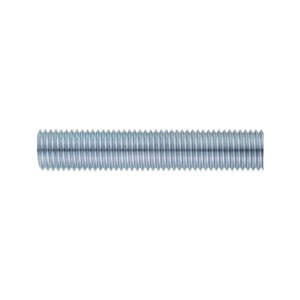

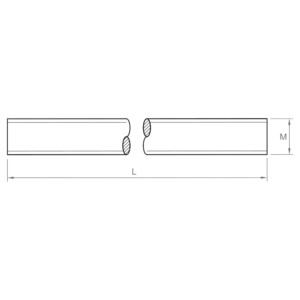

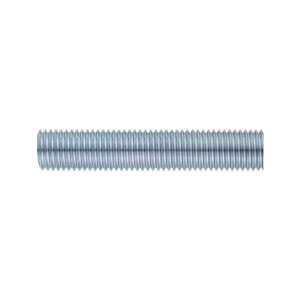

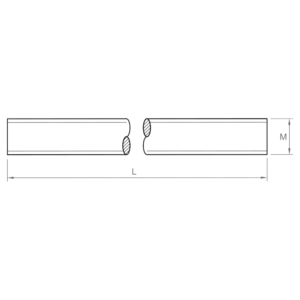

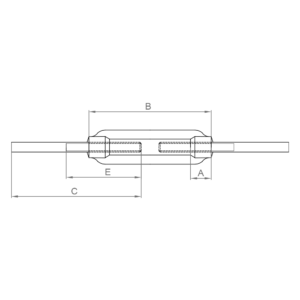

DIN 975 and DIN 976 rods are the most common references, as they offer full metric threads and standard lengths that make them easy to adapt on site by cutting them to size. In general applications, low-strength rods are used for light assemblies or non-structural fixings, while in medium loads and industrial environments, 8.8 rods provide more robust mechanical performance. For cases where greater tensile strength is required, higher grades such as 10.9 can be used.

Available in steel with zinc or hot-dip galvanised finishes, as well as in A2/A4 stainless steel and brass, they allow the appropriate degree of protection to be selected according to the environment, from industrial interiors to outdoor assemblies or corrosive environments.

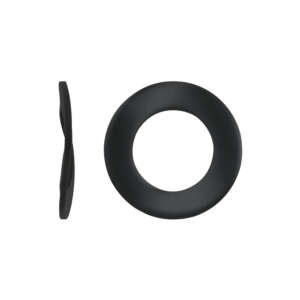

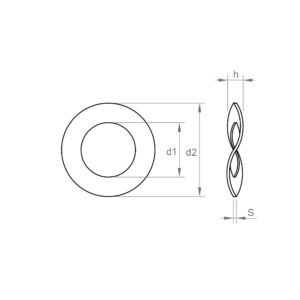

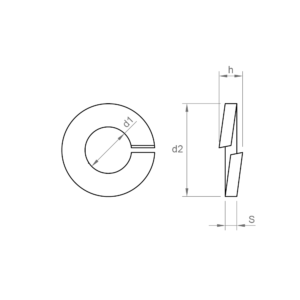

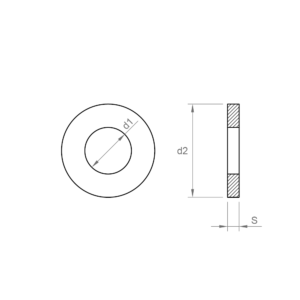

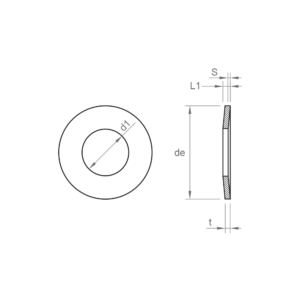

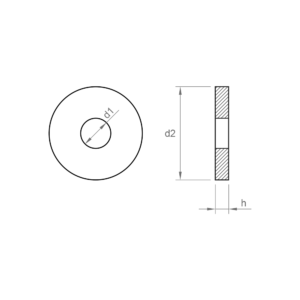

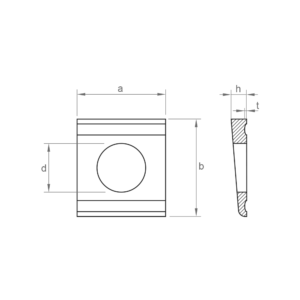

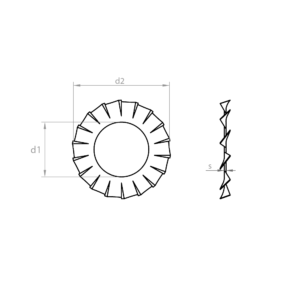

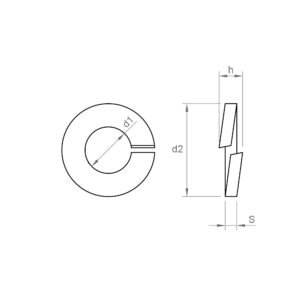

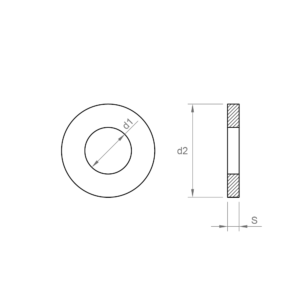

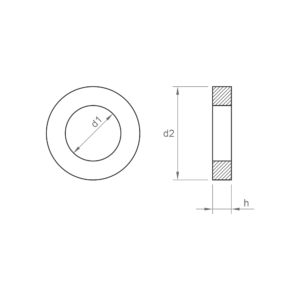

Plain washers (DIN 125) are the most commonly used washers in threaded connections, as they distribute the clamping load evenly and prevent damage to the contact surfaces. In assemblies subject to vibration or alternating stresses, spring lock washers (DIN 127), also known as pressure washers, are used to help maintain a firm fastening and reduce the risk of loosening. For high-load structural joints, structural washers are used, available in different finishes. In addition, the range includes NFE washers, used in specific applications where compatibility with French standards or non-standard DIN measurements is required, offering a versatile solution for different types of assembly.

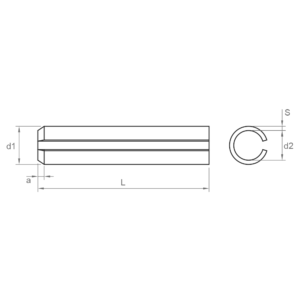

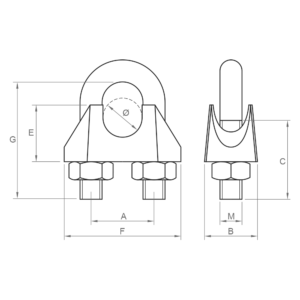

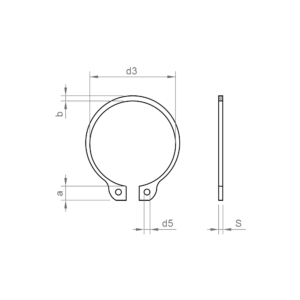

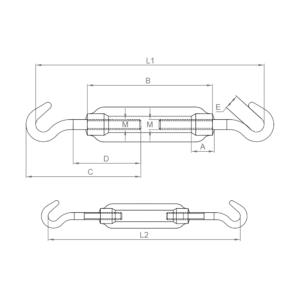

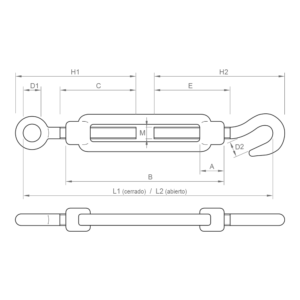

The DIN catalogue is completed with standardised mechanical fasteners such as pins, keys, bolts, studs and shafts, which are essential in assemblies that require precise positioning, load absorption or frequent disassembly. These elements provide reliability in complex industrial assemblies and enable efficient integration into standardised production or maintenance systems.

How to choose the right DIN fastener?

Selecting the correct DIN fastener requires evaluating four key factors:

- Type of application

- Each environment requires fasteners with specific characteristics in terms of geometry, head type or length.

- Loads and mechanical stresses

- It is essential to analyse the tensile and shear forces and the presence of vibrations. Depending on the requirements, the appropriate mechanical strength class is selected:

- 8/8.8: standard joints.

- 10/10.9: heavy machinery and automotive.

- 12/12.9: critical applications with high loads.

- Materials and finishes according to the environment

- Carbon steel: for dry interiors or general assemblies.

- A2 stainless steel: exteriors or environments with moderate humidity.

- A4 stainless steel: coastal areas or chemical industries.

- Special coatings (zinc plating, hot-dip galvanising, Geomet®, Dacromet®) improve corrosion resistance depending on the application.

- Regulatory compliance

- In projects with traceability requirements, it is important to validate compatibility between DIN, ISO or UNE standards to ensure interchangeability and technical compliance.

Advantages of working with DIN standard fasteners

Working with DIN fasteners offers key benefits in industrial projects:

- Universal interchangeability: allows components from different manufacturers to be used without adjustment problems.

- Guaranteed mechanical reliability: each fastener complies with specifications for strength, materials and tolerances.

- Simplified assembly and maintenance: standardisation facilitates installation with standardised tools.

- Quality control and traceability: technical specifications are documented and verified.

- Logistical optimisation: standardisation reduces the complexity of stock and reference management.

DIN fasteners as a guarantee of efficiency and industrial quality

DIN fasteners are not just a technical standard; they are the foundation on which safer, more agile and sustainable assembly processes are built. Their standardisation ensures compatibility between parts, simplifies stock management and guarantees reliable mechanical performance in any environment.

At CHAVESBAO, we offer a complete range of DIN fasteners and advise you to ensure safe and efficient industrial assembly, in accordance with the most demanding quality standards.